Only have 1 minute? Here are 3 key takeaways from the piece?

• Biomyc, a Bulgarian eco-design startup, has achieved a transformative milestone by collaborating with industry giants such as KIA and Mercedes Benz.

• The company focuses on mushroom technology, additive manufacturing, and simulation, leveraging these areas to introduce sustainable technologies and materials.

• Biomyc’s expertise lies in mycelium composite technology, and aims to deliver mycelium-based to the market right now.

Car design has undergone significant transformations over the years, heavily influenced by tech advancements, changing consumer preferences, and an increasing emphasis on sustainability. Thus, for many, driving a car made from sustainable parts also means being committed to environmental consciousness and having a forward-looking approach to technology.

In recent years though, sustainability for mass car producers has become much more than just pivoting to electric cars – it also reflects the whole design process, where plastics are gradually being replaced with more sustainable solutions.

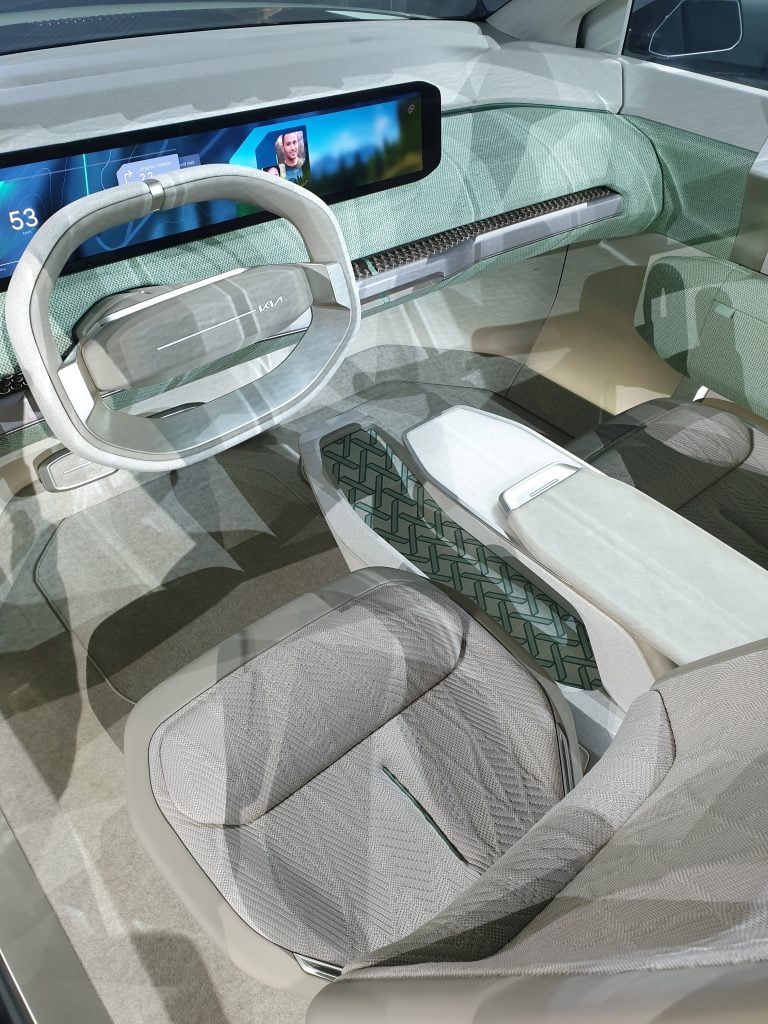

The recent partnership between South Korean giant KIA and Bulgarian eco-design startup Biomyc is one of the examples that is a strong testimony to such developments, as KIA’s new EV3 concept car will feature Biomyc’s designed mycelium composite panel in its interior.

The Bulgarian company’s main expertise is in mushroom technology, additive manufacturing and simulation, and sustainable product design. By combining these three, Biomyc aims to bring sustainable technologies and materials to the market now and not in 50 to 100 years.

“When KIA came to us, they were interested in implementing mycelium composite inside the car. So, we helped them do that by identifying bottlenecks, researching ways to enhance the material’s appearance and durability, and finally designing, prototyping, and helping integrate the first mycelium composite part in a KIA concept car. From packaging to whole products we help companies implement mycelium composite in their workflows – which, simply put, means doing the hard work of researching, designing, prototyping, testing, and merging with existing materials and products,” AtanasEnev, Biomyc’s CEO explains.

Thus, choosing mycelium for the car’s interior demonstrates a shift towards biofabrication, a process that harnesses the strength of materials grown from natural sources. Mycelium, derived from mushroom roots, offers a combination of robustness and a soft, luxurious surface – one of the main reasons KIA wants to use the material.

Furthermore, there is also a strong belief in mycelium composite as the sustainable material of the present and the future – it’s grown on agricultural waste, leading the way in sustainable building, with no resource depletion or environmental waste. Beyond being carbon-negative, mycelium structures are lightweight and insulating, promising energy-efficient buildings with fewer emissions.

“We believe this is the best technology on the market in terms of mass sustainable impact. And we picked the top-down approach to help it gain mass market penetration. Our mission is to implement mycelium composite in as many industry-leading companies as possible, because they are shaping the world – so what they do affects what all SMEs are doing everywhere. That is where the actual impact lies. Our idea is to start big and then as the technology matures help more and more medium and small enterprises use it as well,” Enev explains.

What Biomyc is now trying to do is to develop products that can be both cost-effective and also bring this concept closer to an even wider audience.

“With the support of Norway Grants we developed a standardized packaging system that helps producers manufacture more efficiently and makes mycelium composite packaging as cost-efficient as possible for the end consumer. This year we IP-protected designs based on the standardized system and also developed proprietary software that will help companies that use our designs decrease their sales costs and increase their revenues. This is going to be rolling out in early 2024. We’re working with our first customer to have it implemented in their works as soon as possible,” Enev says.

Business model that is very simple, but takes lots of hard work

One of the biggest challenges for CEE startups is that they find it difficult to find big companies to test their solutions early on and have a proof of concept. For Biomyc though, working with this type of key industry players is becoming a reality, after they previously also did work with German giant Mercedes Benz.

This type of partnership, together with the one that the startup now has with KIA, is a progress that stems from the company’s main mission, which is to bring sustainable innovation for big industry players, but also middle and small companies alike. The business model that the company has is at the same time very simple – but also one takes a lot of hard work.

“Essentially, our business model is tackling big and difficult projects in terms of design, and we use our niche expertise to work with the material to get it done fast and to provide a solution that is as sustainable, innovative, and economically efficient as possible. It’s a very big thing, that the mycelium component is implemented in a KIA concept car and the whole team is very happy to see the real car traveling the world and showcasing its many innovations. Another great result of the project is the insights we gathered during the R&D phase. Everything we learned in terms of how this material reacts to a multitude of methods of coating and protection will help our future customers implement mycelium composite for their products as well,” Enev says.

While every project is different, there is the common notion that both the company and the client are on the same page when it comes to making it happen, he adds. Additionally, one of the most important aspects of working with such big brands is always to be honest about the bottlenecks that the whole process might and will have, the possible problems, and offer tailored solutions.

“To assure absolute success we always include multiple levels of redundancy – we have a plan A, B, C, etc. This is incredibly important to ensure the success of innovation projects with new technologies and materials. And I think customers really like this because it’s a level of honesty that encourages them to dream bigger, be brave, and open minded which is what leads to great innovation. I believe that is exactly why KIA felt confident with us to help them design and implement the mycelium composite component for their concept car. All the optimization, testing, and prototyping was done in our lab in Plovdiv while the design was done in our Sofia office,” Enev tells The Recursive.

A new approach for going sustainable at a reasonable cost

While the technology around the use of mycelium composite is relatively new, it can also prove costly, especially for companies coming from Eastern Europe. By integrating mycelium composite components with paper elements, the system eliminates the need for upfront investment (ranging from one, to two to five thousand euros) from customers for designing, prototyping, and testing purposes.

Instead, as the Bulgarian entrepreneur claims, Biomyc will provide the design IP and the software to mycelium composite producers and then companies interested in mycelium packaging can simply use the proprietary software to customize their packaging and place an order online, streamlining the process and eliminating the need for prototyping, design, and testing costs.

The main goal of the project was to achieve the highest level of cost-effectiveness and versatility to make mycelium composite packaging more accessible to a wider range of companies.

“With solutions like this, mycelium producers can provide effective packaging tailored for the mid-sized companies. One of our priorities is to enable price-sensitive companies from developing markets to use sustainable mycelium composite products,” Enev tells The Recursive.

According to him, when it comes to Eastern Europe specifically, companies care about sustainability but they do not want to achieve sustainability at the cost of more expensive alternatives or decreased efficiency of the eco products they buy.

“What we found out was they did care – it is just that if the price is not right and that if they cannot fit it in their system perfectly from day one, they’re not gonna do it. And perhaps rightfully so. Sustainability should not come at the price of increased cost or lower performance. This seems very logical to us as most companies from the region achieve market success by producing good products at a great price. Therefore, you cannot force businesses to risk their advantage on the market in exchange for sustainability but rather help them achieve it in an economically and functionally efficient way,” he says.

However, while conditions allow the wider use of mycelium composite to flourish, Biomyc remains focused on its mission to help the material achieve mass market penetration.

“Every young technology needs time to mature and if you give it 100 years, mycelium composite is gonna compete effectively in price, function, and volume with plastic. It took plastic 150 years of development to make manufacturing a single product take less than a second and cost very little. This makes plastic a great fit for a capitalist market. The same will happen with mycelium composite technology. But until that occurs and the technology matures, it is our company’s mission to get this to the market right now using clever design and innovation,” Enev concludes.