Even though quantum technologies are still in their infancy, commercial potentials are starting to show more and more. Investments are following that as well, with 68% of all quantum startup investments since 2001 occurring in the last two years alone.

In this budding field, QuantumDiamonds is cutting through with its approach to quantum sensing. Based in Munich, this startup is crafting atom-sized quantum sensors that have the potential to redefine measurement in various high-tech industries. Such sensors are greatly sought after in semiconductor manufacturing, medical diagnostics, and other industries that require highly precise measurements.

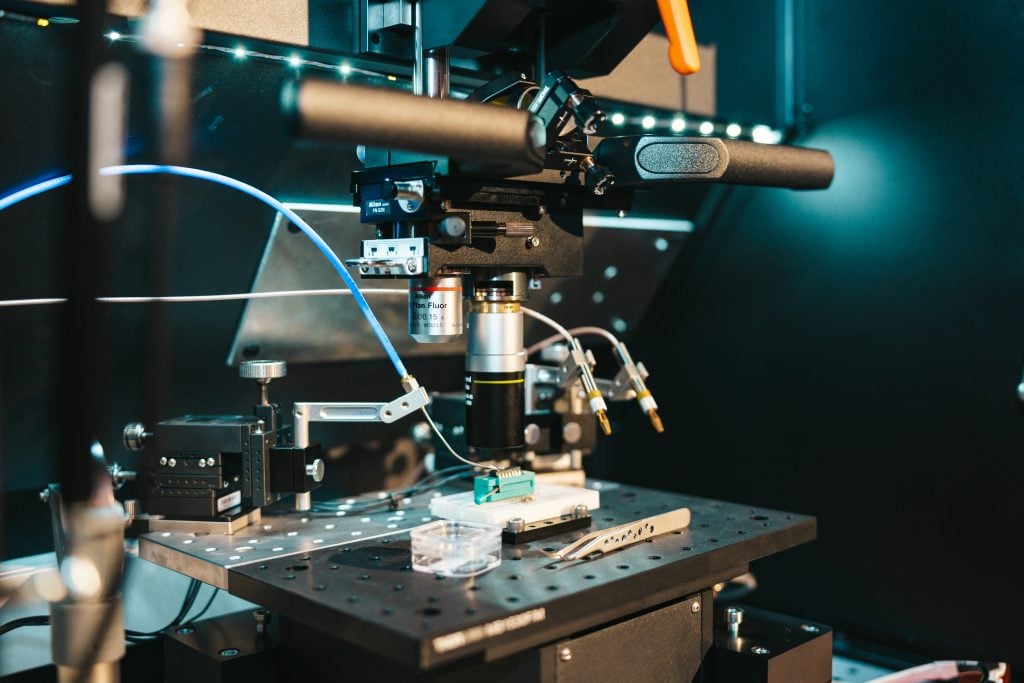

QuantumDiamonds recently announced the launch of the QD m.0, the world’s first commercial quantum device designed for microchip quality inspection. This device enables accurate, non-destructive detection of faults in complex chip architectures necessary for AI, complementing traditional testing methods with 3D inspection capabilities.

So we couldn’t miss an opportunity to talk about current quantum sensing opportunities and innovations with Kevin Berghoff, CEO and Co-Founder of QuantumDiamonds.

“The Quantum Sensing”

At the core of QuantumDiamonds’ innovation is the use of nitrogen-vacancy (NV) centers, solid-state qubits embedded in diamonds. These NV centers are known for their remarkable ability to measure magnetic fields, temperature, and pressure with unparalleled sensitivity and precision.

“We’re able to break physical barriers in terms of spatial resolution and sensitivity, unmatched by classical sensors,” Berghoff explains. “What’s exciting is that these sensors operate at room temperature and without the need for additional shielding“.

Non-destructive analysis of microchips

This breakthrough has significant implications for industries like semiconductor manufacturing, where the complexity of microchips has skyrocketed, making it increasingly difficult to detect defects deep within multiple layers. Berghoff elaborates:

“When we talk to semiconductor companies, they tell us they can look at the first layer of the chip with optical microscopes, but they cannot assess whether there are defects in the second, third, or fourth layers.”

The QuantumDiamonds’ first commercial device, the QD m.0, a two-meter-high microscope-like machine, allows for real-time, non-destructive analysis of microchips. Semiconductor companies can use it in the manufacturing process without damaging the chips, and still sell them afterward.

“You just put the chip in, run current through it, and we image layer by layer what’s happening inside.”

Applications beyond semiconductors

While QuantumDiamonds is already making waves in semiconductor manufacturing, Berghoff sees its technology expanding into other fields, particularly medical diagnostics. “All kinds of medical compounds have very small magnetic fields,” he says.

“For example, tumor cells versus normal cells have different magnetic footprints. In the long term, this technology could enable sensing magnetic fields in biological samples, potentially leading to new tools in medical diagnostics”

Berghoff also highlights potential applications in battery research. Much like semiconductors, batteries require non-destructive testing to ensure quality and performance.

“A similar approach can be applied, but with different dynamics,” he notes. “The goal is to increase output and ensure that the batteries work as intended when integrated into devices.”

From concept to market

Bringing a complex technology like quantum sensing from concept to market has been no easy feat, as Berghoff recounts. “One of the biggest challenges we faced was interpreting the massive amounts of data our devices generated,” he explains.

“The hardware team built everything, and then we realized it was generating terabytes of data every second. We had to come up with a machine learning algorithm to interpret this data, which was quite challenging, but now it works.”

Looking ahead, Berghoff remains focused on expanding QuantumDiamonds’ reach. Their recent selection for German Accelerator U.S. Market Access Program will help the company break into the US market.

Even though their main work revolves around science, scaling the business, driving sales and maintaining customer satisfaction is what will eventually decide on their success. Hopefully, with Berghoff’s experience they are prepared for that as well.

Reflecting on his path from McKinsey & Company to founding a deep tech startup, Berghoff acknowledges the importance of his consulting background. “My time at McKinsey helped me approach QuantumDiamonds with a strong business perspective,” he explains.

“I’m not the quantum physicist, so I focus on where the problems are and where the money is. Who will pay for these advanced microscopes? That’s the question that drives me.”

A vision for the future

QuantumDiamonds is now at the point where their quantum sensing product is ready for mainstream industrial use. However, Berghoff believes that the potential of quantum technologies goes far beyond that.

“We hope,” Berghoff concludes, “QuantumDiamonds will be the first company to commercialize quantum sensing, not just for semiconductors, but for biology, chemistry, and other critical fields.”