One doesn’t think too often of the lotus leaves floating on lakes or rivers, or even the ones in our garden ponds. But not everyone disregards them. What if I told you that a synthetic lotus leaf could generate power for your household? A study on a successful lab-style prototype of artificial leaves that can produce clean fuel from water and sunshine was just released by a team of Cambridge University researchers led by Prof. Erwin Reisner.

Since 2019, the research team has been focusing on streamlining the procedures for producing renewable energy. The gadget was heavy due to the usage of thick glass substrates and moisture-protective coatings in the original prototype of their invention, but their most recent product optimization managed to reduce the amount of material utilized, making the device light enough to float on water like a real lotus leaf.

The Winton Programme for the Physics of Sustainability, the Cambridge Trust, the Royal Academy of Engineering, and the Engineering and Physical Sciences Research Council all provided financial support for the study.

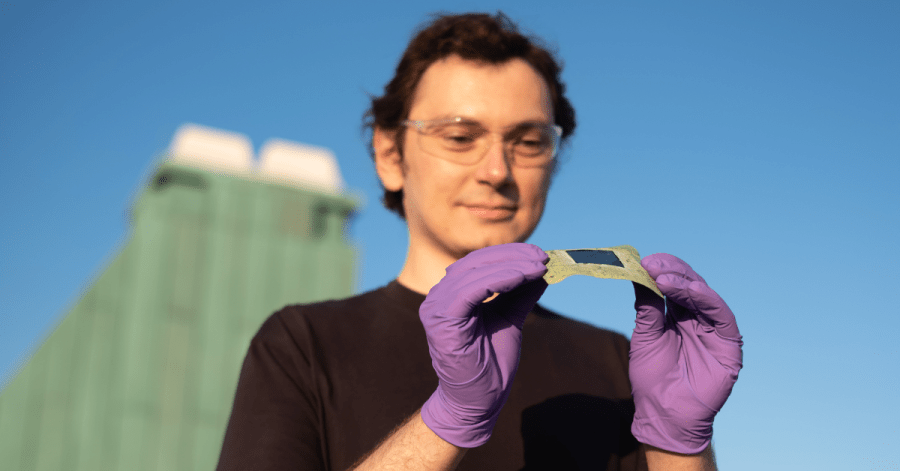

The Recursive spoke to Virgil Andrei, A Research Fellow at St John’s College in Cambridge, to learn more about the technology underlying the leaves and the next steps required to bring the product to market.

The Recursive: When did you discover your passion for chemistry?

Virgil Andrei, Research Fellow at St John’s College in Cambridge: I think it was in high school. I have always been interested in science. First mathematics and physics, but I quite liked that chemistry gave me more opportunities to learn how organic processes worked. You have more directions you can pick from. There is inorganic chemistry or synthetic chemistry, and organic chemistry. I could also go into physical chemistry or analytical chemistry. So it was very interdisciplinary, which meant that one can really combine many, many different concepts and go in different directions.

Where did your inspiration for artificial leaves come from?

There are already some technologies such as photovoltaic electrolysis where solar cells are connected to catalysts, and those can produce fuels. But the problem is that the systems are big and complex with additional wiring, reactors, typically corrosive solutions, and expensive catalysts. Logically, all of these components drive up the cost of the system. Whereas our idea was to mimic nature. By just having one simple panel where you have all of these components integrated. So you have the light absorption and the catalysis in one simple panel. And then if everything is integrated properly, the “photosynthesis”, in principle, is done so much easier. This is what makes artificial leaves different from other solar fuel technologies.

Could you just briefly tell me how the technology behind artificial leaves works?

In plants, you have this process called photosynthesis, where you use sunlight to convert small molecules like water and carbon dioxide into sugars and oxygen. In our case, we take this basic concept but simplify it because natural photosynthesis is a very complex process that has low efficiency. So we simplified it by introducing better light absorbers and better catalysts. And by doing so, we managed to obtain these artificial leaves which can produce products of interest and useful reactions.

In our case, we had panels made of two light absorbers. On one side we placed bismuth vanadate, an oxide which produces oxygen from water. On the other side, we placed the light absorber, Perovskite, which uses the rest of the light and converts CO2 and water into hydrogen and carbon monoxide. This mixture of carbon monoxide and water is called syngas. It’s very important in industries for the production of liquid fuels that we actually use in our everyday cars.

If syngas produced by the leaves is a sufficient substitute of fuels, what is the next step in developing and scaling the prototype?

Scaling up the prototype is definitely our aim. We want to have a carbon-neutral cycle. To take CO2 from the atmosphere and use that to make the fuels that we need instead of using more fossil fuels that then get dumped into the atmosphere. So, right now, in principle, our technology can be scaled up. These floating artificial leaves can be made on flexible, lightweight straps and substrates, and therefore mass produced.

The problem is that we still need specialized equipment. If we want to build a square meter scale we also need to adapt or optimize some of the procedures. And once we have the equipment, once we have those square meter prototypes, then we can really go on and test them on larger plants which then will provide us with much stronger arguments to move into large scale applications and sell the invention as a commercial product. That is not happening now, I am speaking more like 5-10 years down the line.

What is one hardship you struggled to get around during the research and development of the prototype?

There were several factors. Obviously, this floating leaf was quite a different system from what has been developed before. So we really had to rethink and redesign the entire device structure and for each individual component, let’s say, a substrate, we had to figure out how to deposit all those layers on top of it. Additionally for the encapsulation, we had to figure out how to make very thin plastic layers. That is why we had to collaborate with people who could deposit these layers in a specific way. Even though it works similarly to previous leaves, the fact that we reduced the amount of material thus making it lighter changes a lot of things.

Afterwards, we also had to deal with the pandemic. Many facilities were closed so it took a while until they got reopened for us to regain access to materials, as well as instruments. There was also reluctance from the community because there are people who have been working 20 years on similar technology, therefore they would object to others coming up with a very different approach. But overall, we managed to overcome all of these challenges.

You revolutionized the whole prototype by making it float as opposed to the previous prototype that used glass encapsulation. How did you come up with the concept of making the leaves float?

Back when we were working with the prototype that was covered in glass we wanted to make a leaf that can perform CO2 reduction because typically these devices can split water into hydrogen and oxygen, but they can’t really do more challenging reactions. However, we managed to demonstrate that the device could do the CO2 reduction, so the next step was to trim down the number of materials we use. This way we would have a prototype that would not only work as a leaf but would also look like one.

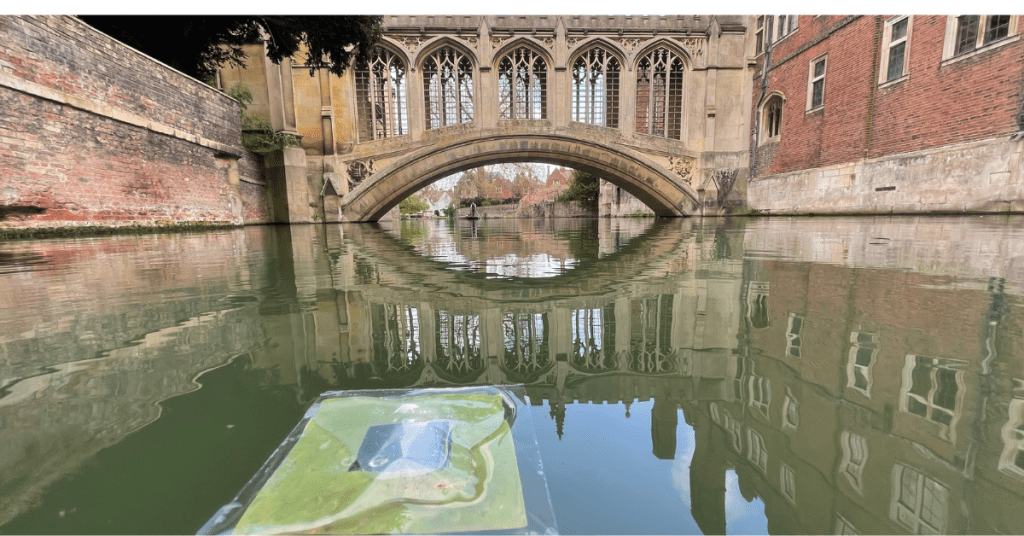

Once we developed the technology, we moved on to figuring out a design that would be easily scalable. In principle, it has always been scalable, but we still had to work on it and make it more efficient. It was a pleasant surprise to see that the device was so light that now the bubbles that formed under operation made it float to the surface of the water.

It is a funny story because it was me drawing a figure on paper where the leaf is kind of floating in the water. And I was thinking okay, let’s try if it actually works, and it did. The added value of the floating is that even when scaled up, the product will not have to compete for landmass or affect agriculture or housing areas. The leaves could be placed anywhere – on lakes or rivers, along shorelines and even around islands. And in this way, it will produce fuel without the need to use land.

On that note, in which industries do you see this invention being applied?

There are several applications. What has been done already was making these flexible solar cells, which could be produced by roll-to-roll procedures, so that those can already be prepared on a larger scale, or continuously. I do not know if they’re commercialized yet, but people definitely have shown that they can build prototypes. So then you can have very thin plastic sheets or coatings, they’re transparent, and you can just put them on your windows and produce electricity.

We also have these flexible, bendly mobile phones whose screens are very similar in a way to the thin-layer, artificial leaves. This type of bendy, conductive material is something people started developing maybe 10 years ago. So that’s another application.

Otherwise, it could be applied almost with any technology. It’s useful when you can trim down the material costs because then you can just produce things easier and cheaper.

What is your next step regarding the research or if it is done, how are you planning to proceed with the development of the product?

We are not necessarily calling it a product yet. But now we need to make sure to secure some funding and purchase or develop equipment that can help in the production of artificial leaves on a larger scale. And this could probably take five years, but once we have the funding and equipment then we can push toward the application and commercialization of the product. Yet, we want to make sure the product stays on track and develops in the right direction. That is why for now we will have the intellectual property rights. We wouldn’t want to just hand over our ideas, as we still have things to develop before we could see a proper product out.

If you could speed up climate action, what would your approach be?

It’s a matter of deploying climate technologies on a larger scale. There are already very good technologies for making solar panels and wind turbines for example. Batteries are still a bit of a problem. That’s why we still need fuel. Because energy transport and storage are still hardships, I guess we could all just implement more of the technologies that are already well established and quite advanced. So we need more applications across various fields to start making a difference. But also, we could adjust our behaviour and take responsibility. Nowadays, consumption is a big problem.

Personal responsibility is important, yet how close is climate tech to making significant steps towards carbon neutrality in your opinion?

Well, I think what you see nowadays is that the price of solar cells decreases significantly and there are way more installed than was predicted. And obviously, this is very promising. The problem is that electricity only makes up one-fifth of our energy consumption. So we either need to switch the whole infrastructure and industry to electricity, or we need to find a way to use that electricity to make fuels sustainably. I think the methods for making fuels are still quite recent inventions, namely works in progress. So it will take a bit longer to develop but we need to identify how efficient the current engines are or how much they emit so we can optimize the process. Although, again, it’s also a matter of personal choice what type of energy you want to use. So the more we convince people to consume less or persuade them of the good effects of eco-friendliness, the closer we can get to carbon neutrality.